They all work together in a process known as "automated stereolithographic bioprinting."

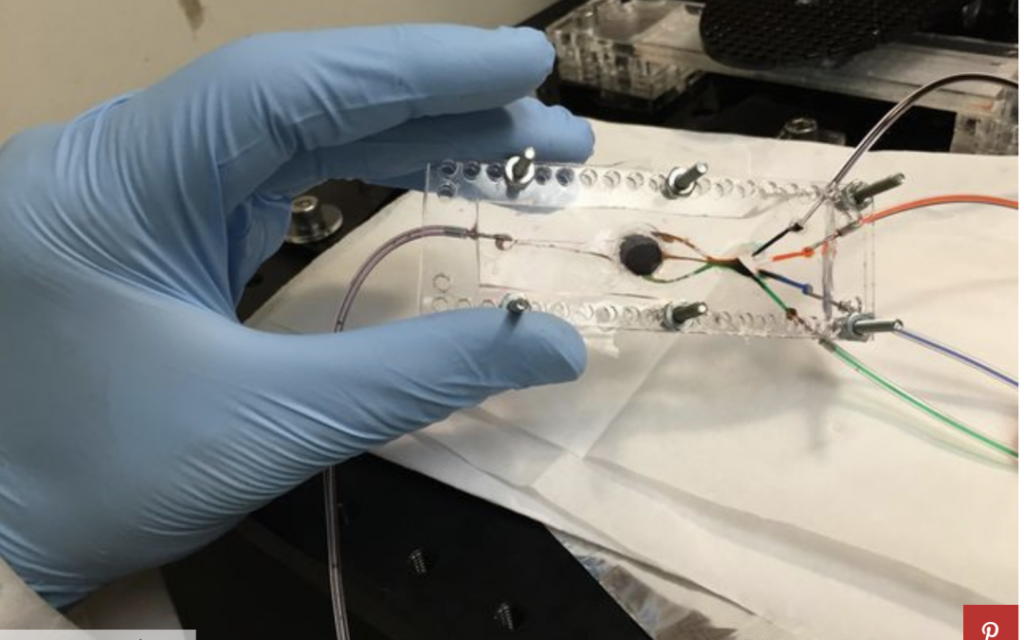

David Grossman writes in popular mechanics that scientists are hoping that a specially adapted 3D printer made to build therapeutic biomaterials will help aid medical research by printing test materials so complex as to closely approximate real human tissue. Khademhosseini’s 3D printer has two key parts that give it this complexity. One of them is a custom-built microfluidic chip which handles the flow of liquids inside micrometer-sized channels. It has multiple inlets that each “prints” a different material. It also has an an array of over a million tiny mirrors, each of which move independently. Read more